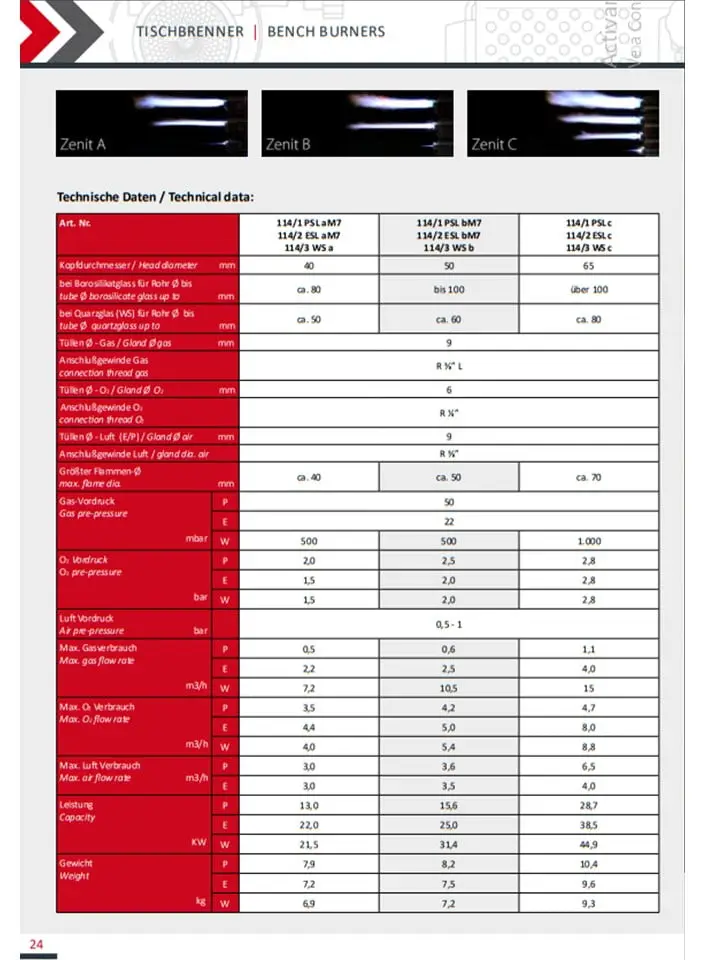

Arnold Glass Blowing Noiseless bench Burner, Zenit

Arnold Glass Blowing Noiseless bench Burner, Zenit Model No 114-1 Pb for propane,Oxigen &Compressed Air Noiseless bench burner ZENIT . Head diameter 50 mm

For tube diameter over 100 mm

50mm ZENIT BENCH BURNER (TORCH) by HERBERT ARNOLD

Herbert Arnold Zenit 50 mm, Noiseless Bench Burner.Model No 114-1 Pb GLS/ELS/PLS

Noiseless bench burner, for gas and oxygen, burners for natural gas and propane with special flame stabilization

Noiseless Surface-Mix Herbert Arnold for propane and oxygen, with special flame stabilizing system that allows the burner to operate with a surplus of air – therefore – with a cooler flame. Burner is mounted on a solid cast iron foot with Ball Joint.

Head Diameter: 50mm Works Borosilicate Glass of a Tubing Diameter – Up to Approximately 100mm. Gland Diameter – Gas for Hose of Size: 9mm. Connection Thread Gas: G 3/8″LH. Gland Diameter – Oxygen for Hose of size: 6mm

Herbert Arnolds noiseless bench burners that are used with propane, oxygen, and optional compressed air.

Arnold Glass Blowing Noiseless bench Burner, Zenit

Arnold Glass Blowing Noiseless Bench Burner, Zenit

Description

The Arnold Glass Blowing Noiseless Bench Burner, Zenit, is a specialized piece of equipment used primarily in glassblowing and glassworking. It is designed to provide a controlled flame for heating and shaping glass without producing significant noise, making it ideal for use in laboratories and workshops where a quiet environment is essential.

Use

- Glassblowing: The burner is used to heat glass to its melting point, allowing for shaping, blowing, and forming of glass objects.

- Glassworking: Ideal for detailed work, such as creating intricate designs or repairing glass items.

- Laboratory Applications: Used in scientific settings for glass manipulation, including the creation of laboratory glassware.

Applications

- Artistic Glass Production: Artists utilize the burner to create sculptures, ornaments, and functional glassware.

- Industrial Glass Manufacturing: Employed in the production of glass components for various industries, including automotive and construction.

- Educational Purposes: Used in educational institutions for teaching glassblowing techniques and principles of glass science.

Importance

- Noise Reduction: The noiseless operation is particularly beneficial in settings where concentration and a calm atmosphere are required.

- Precision Control: Allows for fine-tuning of the flame, enabling precise heating of glass for delicate work.

- Safety: Designed with safety features to minimize risks associated with glassblowing, such as burns or accidental fires.

Considerations

- Maintenance: Regular maintenance is essential to ensure optimal performance and safety.

- Training: Proper training is necessary for users to handle the burner effectively and safely.

- Compatibility: Ensure compatibility with the type of glass being used and the specific requirements of the glassblowing project.

The Arnold Glass Blowing Noiseless Bench Burner, Zenit, is a vital tool in the field of glassworking, providing artists and professionals with a reliable and efficient means of manipulating glass while maintaining a quiet working environment.